3D Scanning

REVERSE ENGINEERING

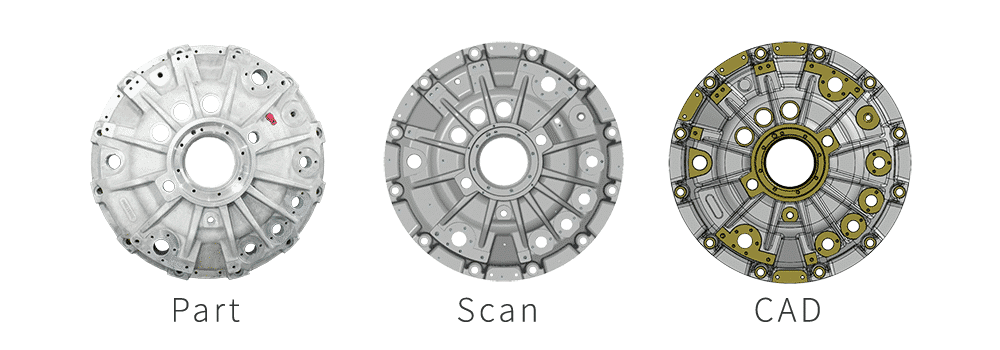

You can count on Creaforms 3D Scanners if you need to generate 3D CAD models from existing objects (as-built), whether to determine the original design intent, to modernize manufacturing processes or to design a new part to fit to a legacy part, for instance.

What is Reverse Engineering?

Bridging Physical & Digital Worlds

• Capture CAD data from your object

• Design a new part to fit

• Refine performance surfaces

• Update CAD models for part-tooling needs

• Redesign a product/part without manufacturing defects

• Streamline your manufacturing process

CAD Development

Reference Bodies

Assembly Mapping

Casing

BOM Creation

Archiving

Digitise Your Object

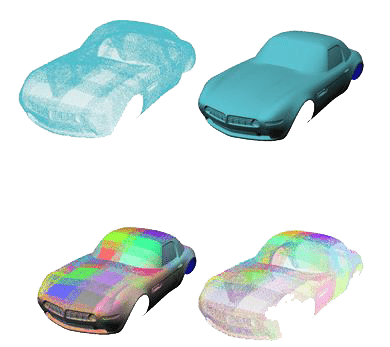

With reverse engineering you can digitise almost anything into workable 3D CAD data. By digitising your products and parts, you can modernise your manufacturing and product development processes and eliminate the need for physical inventory. Reverse engineering through 3D scanning makes it possible to easily and quickly achieve a highly accurate 3D digital model of the assembly and all existing components of your part. Our reverse engineering services can help you build the best possible product. Learn More >>

Why Use Reverse Engineering?

When to use Reverse Engineering?

• Interoperability

• Lost Documentation

• Product Analysis

• Digital Update & Correction

• Academic & Education